GUIDED TOUR

Unicast Company takes pride in its work and state-of-the-art facilities. The following will give you a better feel for some of the technology Unicast incorporates in its work.

MELT DEPARTMENT:

- Unicast has the capacity to melt up to 80 tons per day in a 42″ I.D. Cold Blast Cupola

- The iron is then transferred into a 32-ton Electric Channel Induction Furnace

- The iron is transferred to pouring ladles and refined to specific chemistry and temperature for pouring

- The characteristics of our iron allow us produce an extremely wide range of unique and unusual castings Core Room and Pattern Shop

CORE ROOM AND PATTERN SHOP:

- The production of castings with internal cavities requires cores which are is engineered to maintain their shape and size until the iron solidifies

- The type of casting being produced determines whether a no-bake or hot-box core is used

- Pattern maintenance and minor pattern problems can be addressed in our pattern department

- We also have available several qualified pattern shops to support your needs

- Pattern storage is available for quick turnaround

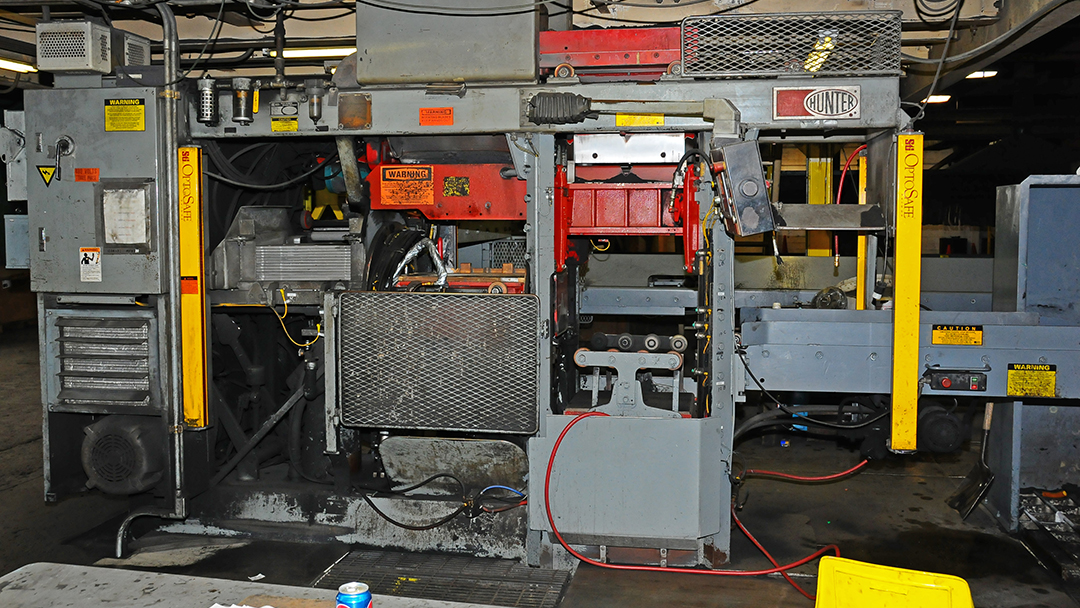

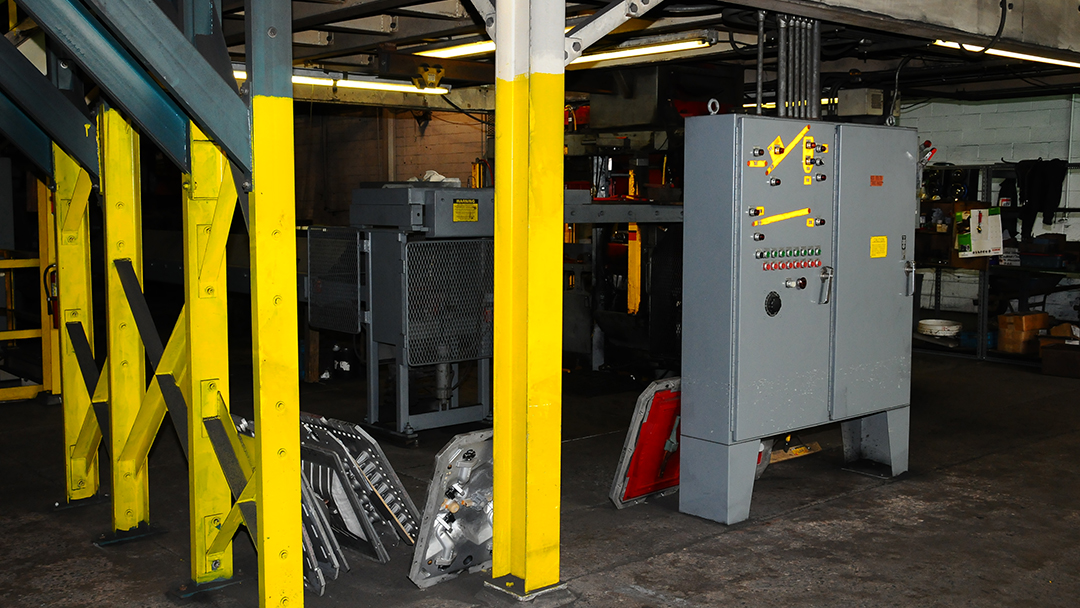

MOLDING DEPARTMENT

Automatic Molding

- FBO-II manufactured by Roberts Sinto Corporation

- HMP20E manufactured by Hunter

- These machines produce exceptional castings using flaskless technology, allowing Unicast to maintain its high levels of quality while utilizing the latest technologies

Cope and Drag and Floor Molding

- Lower volume, unique and difficult large castings are produced in these areas

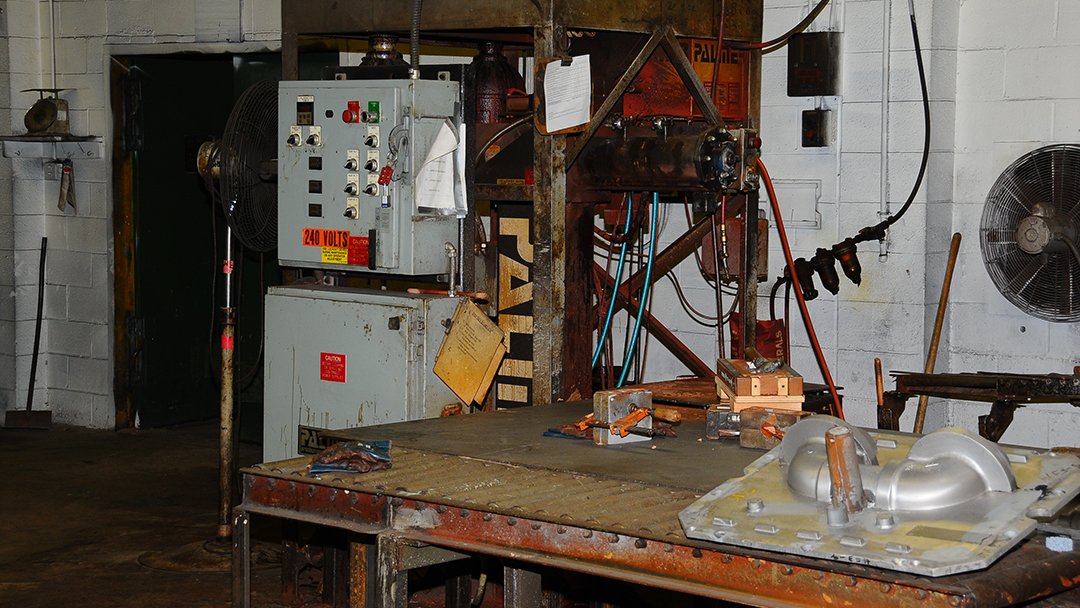

FINISHING AND SHIPPING:

- All castings are shot blasted and individually inspected

- Gates and parting lines are ground off to produce the finished castings per customer specifications

- The various grinding stations include wheel and hand grinding and vary in size from 8” to 30”

- A final inspection occurs before packaging

- All castings are carefully packaged in customer designated containers